Define Capacity Planning Stages (SAF-770)

Step-By-Step Guideline

The purpose of this procedure is to set-up the major stages through which an order flows in your company so that you can use the Capacity Planning function to estimate when orders can be completed and decide what changes you need to make to the capacity that is available for each stage.

A Stage does not represent an activity but rather one or more RESOURCES or WORKSTATIONS.

-

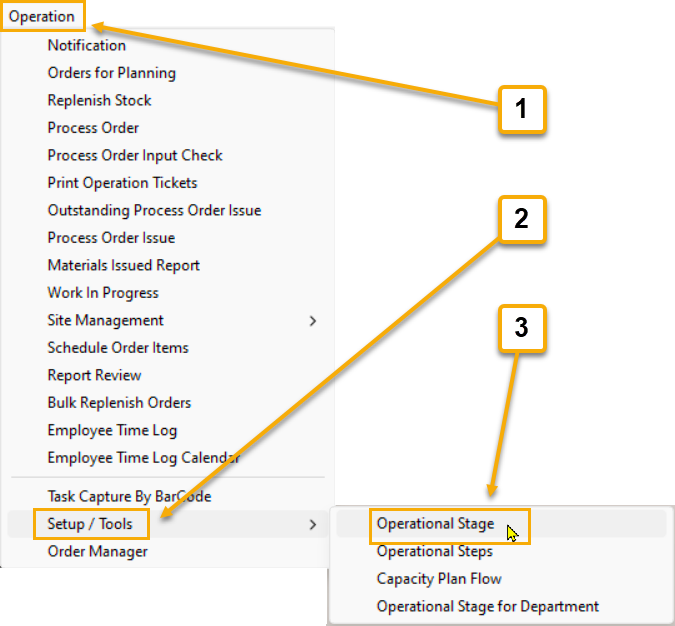

Select the Operation menu item on the main menu.

-

Then click Setup / Tools at the bottom of the drop down menu.

- Click Operational Stage from the side menu.

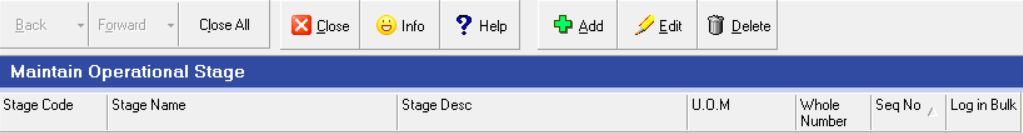

The system will open a screen titled "Maintain Operational Stage".

This screen lists all of the Production Stages that you have defined in the system.

- When you initially enter the Maintain Capacity Planning Stage screen the list will be empty. To define the stages for your company, click the Add button at the top of the form.

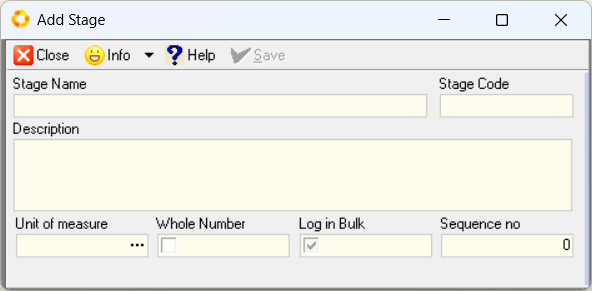

The system will display the Add Stage screen.

The Add Stage screen allows you to enter information about the Stages that exist within your company.

-

Enter the Name of the stage you wish to define in the Stage Name field.

-

Enter a Code that you can use to identify the stage on labels and other printed documents in the Stage Code field.

Use any format that makes sense in your business. -

Enter a Description for the stage (if this is necessary) in the Description field.

-

Select an appropriate Unit of Measure used to measure the Available Capacity in this stage in the Unit of Measure field.

This could be a time unit of measure or it could be a physical dimension such as linear meters or square meters or it could simply be descriptive text such as "Board" or "Component" or "Part".

-

If you have entered a logical unit of measure such as each, then you should tick the Whole Number field to set it to ON.

This will then force you to define the Capacity Required for individual steps and the tracking of progress to use whole numbers.

If you have selected a physical unit of measure such as time, square meters, linear meters and so on, then you should probably set the Whole Number setting to OFF.

- You can control the sequence in which the Stages are displayed and used for scheduling.

To set a sequence number enter this in the Sequence Number field. You should define the Sequence for the Stages according to the flow that orders typically take through your factory.

So cutting should be first, edging second, CNC third and so on.

-

Once you have completed defining all the fields on the Stage screen, click the Save button.

-

Click the Close button.

Then repeat the above steps until you have defined all the stages in your company.

This is the end of the procedure.